Glass cutter is a common tool used to create cut lines in glass and split it. It usually consists of a blade with an edge and a grip. The edge of the blade is very sharp and is capable of cutting through glass surfaces. A glass cutter is used by placing the blade on the spot to be cut, then applying the proper pressure and moving the blade so that its edge leaves a visible and precise scribe line on the glass. Once the scribing is complete, the glass can be split using other tools or with a combination of pressure and movement.

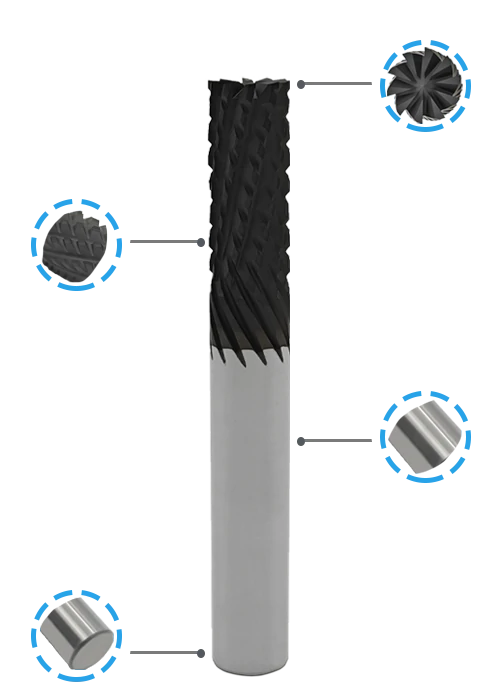

Improved tool hardness: Diamond is the hardest material known to man, and its coating effectively increases the hardness and wear resistance of the tool, thereby extending the tool’s service life.

Better dimensional accuracy: The bottom chamfer design can improve the dimensional accuracy of the machined parts by reducing tool deflection and improving the stability of the cutting process.

Increased stability: Large diameter design can increase the stability of the tool, reduce the vibration during the cutting process, lower cutting forces and surface roughness, and improve the quality of the machining.

Low thermal expansion coefficient: High-quality bar materials for carbon fiber cutting tools have a low thermal expansion coefficient, which enhances the dimensional stability of the tool and ensures the accuracy of the machined parts.

Need Help With Easier Industrial Solutions? We Are Experts!